Common abrasive belt joint methods

Common abrasive belt joint methods

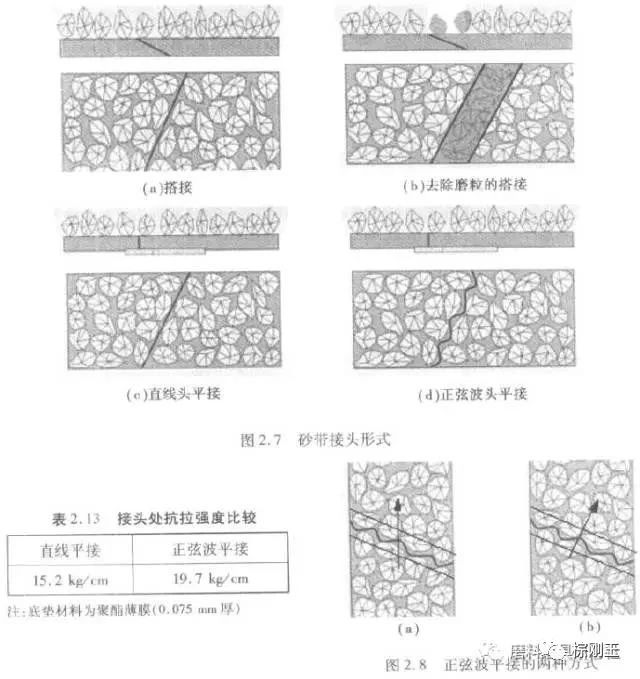

There are two common joint forms: lap joint and flat joint (also called butt joint or lining), while flat joint can be divided into two forms according to the shape of cut edge, namely straight flat joint and sinusoidal flat joint, as shown in the figure.

Wherein (a) and (b) are lap joints, suitable for all kinds of sand belt joints. In (b) the abrasive grain at the joint are removed so that the abrasive belt is processed without marks at the joint. Attention should be paid to the running direction of the overlapped sand belt when it is used. The layer on the joint should be the entry direction, so that the joint can bear the pressure and shear force when it is grinding. And shear force is also help to the joint stress.

(c) and (d) are flat joint sand belt conditions. A very thin (about 0.075mm) but high strength polyester film downstream of the joint ACTS as a substrate. The joint belt is suitable for high speed grinding and precision grinding with unrestricted steering. Compared with (c) and (d), the linear flat connection strength of (c) is not as good as that of (d) sine wave type connection (Table 1), and the flexibility is not as good as the latter. This is because the sinusoidal waveform in addition to more reliable bond, the substrate itself also has the role of phase locking. Sinusoidal joint is a relatively new type of joint. There are two shear forms of sinusoidal waves as shown in FIG. 2.8, and the use of FIG. (a) can achieve a more uniform stress distribution.

sand belt manufacturer,abrasive belt factory,grinding bands,abrasive cloth conversion

In a word, both of them are beneficial to increase the wave-stuck strength of the lining material and reduce the phenomenon of binder flanging in the straight joint, which not only makes the thinner and less lining material have greater tensile strength, but also makes the joint sand belt run smoothly and is not easy to appear grinding marks. At present, lap joint sand belt is gradually replaced by flat joint sand belt, which is due to the technological progress of joint adhesive and joint lining material, the reduction of relative price and the more smooth access to these materials and other factors.

abrasive belt | Zirconia Alumina Abrasive Belt | Compact Abrasive Belt | Silicon Carbide Abrasive Belt

Copyright ©Henan Sanders Abrasives Co.,Ltd All Rights Reserved. Technical Support By Yihong Century Network Technology Co., Ltd. Sitemap

Henan Sanders

Abrasives Co.,Ltd

Henan Sanders

Abrasives Co.,Ltd