Selection and principles of polishing abrasive belt abrasives

Selection and principles of polishing abrasive belt abrasives

Abrasive selection

Physical and mechanical properties of abrasives Abrasives are the mainstay of cutting during the grinding process. They directly bear the cutting work and are the fundamental factors that the grinding wheel can produce. Abrasives must have high hardness, heat resistance, thermal stability and chemical stability, and should have a certain degree of toughness in order to withstand a certain amount of grinding force.

aluminium abrasive belt,polishing wheel,flap disc factory,grinding wheel

Abrasive selection principle

When grinding materials with high tensile strength, it is beneficial to select corundum abrasives with higher toughness. Grinding materials with low tensile strength is beneficial to the selection of brittle silicon carbide abrasives.

In addition to considering the tensile strength of the workpiece material, the hardness of the workpiece material is also the primary basis for selection when selecting the abrasive. In general, the hardness of the abrasive should be 2-4 times higher than the hardness of the workpiece material. Otherwise, the abrasive grains with lower hardness will be quickly passivated during high-speed cutting and lose the cutting ability, so that the durability of the grinding wheel is too low and the cutting is affected. Efficiency and quality of processing are not guaranteed. Therefore, the higher the hardness of the workpiece material, the higher the hardness of the abrasive.

aluminium abrasive belt,polishing wheel,flap disc factory,grinding wheel

The choice of abrasive properties should also take into account the chemical reactions that may occur in the grinding process system. In the grinding contact zone, abrasives, binders, workpiece materials, grinding fluids and air are prone to spontaneous chemical reactions under the catalysis of grinding temperature and grinding force. Tests have shown that silicon carbide grinding tools are ground. In steel, the wear of the abrasive tool is faster than that of the corundum abrasive when grinding the steel. The main reason is that there is a strong chemical reaction between the silicon carbide abrasive and the steel.

In addition, the thermal stability of the abrasive should be considered when selecting the abrasive. When grinding some hard-to-grind materials, when the grinding zone is prone to high temperatures,

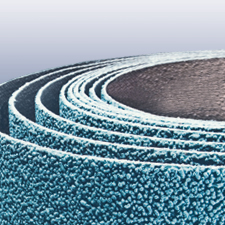

abrasive belt | Zirconia Alumina Abrasive Belt | Compact Abrasive Belt | Silicon Carbide Abrasive Belt

Copyright ©Henan Sanders Abrasives Co.,Ltd All Rights Reserved. Technical Support By Yihong Century Network Technology Co., Ltd. Sitemap

Henan Sanders

Abrasives Co.,Ltd

Henan Sanders

Abrasives Co.,Ltd